Foreword

Recently, researcher Tao Fei of Shanghai Jiaotong University is the corresponding author, and Tan Chunlin, a doctoral student of Shanghai Jiaotong University, is the first author of the paper. The paper "Direct carbon capture of cyanobacterial cell factory for the production of high-performance biodegradable plastics" was published in "Green Chemisty". Using cyanobacterial cells as chassis cells and carbon dioxide as raw material, PLA (polylactic acid) was successfully synthesized directly.

Through the combination of systems metabolic engineering and high-density culture strategies, the efficiency of PLA synthesis by cyanobacterial cell factories was increased by about 270-fold.

Plastic pollution is one of the greatest challenges of the 21st century. Human activities generate a large amount of plastic waste, form white pollution, and damage the ecology and human health.

Currently, people usually use incineration and landfill to dispose of plastic waste. However, these two methods will bring further environmental pollution problems. Landfilling occupies land resources, which not only takes a long time to process, but also pollutes the environment. The toxic gas and smoke generated by incineration will also cause secondary pollution to the environment.

Therefore, the production of degradable plastics to replace traditional plastics and avoid pollution from the production source is considered to be the ultimate solution to the problem of plastic pollution. Considering various factors, polylactic acid (PLA) is currently the most ideal candidate for degradable polymers.

Traditional PLA manufacturing uses grains such as corn as production materials, which will lead to resource competition between material production and food supply, and its sustainability is problematic. Therefore, a new generation of PLA industrial production technology based on non-grain raw materials needs to be developed urgently.

Recently, the Food and Environmental Biotechnology Team (FEMlab) of the School of Life Science and Technology of Shanghai Jiao Tong University used synthetic biology technology to develop a "negative carbon" production technology for a new generation of degradable plastic PLA, which provides a new way for the synergistic solution of these two problems. ideas.

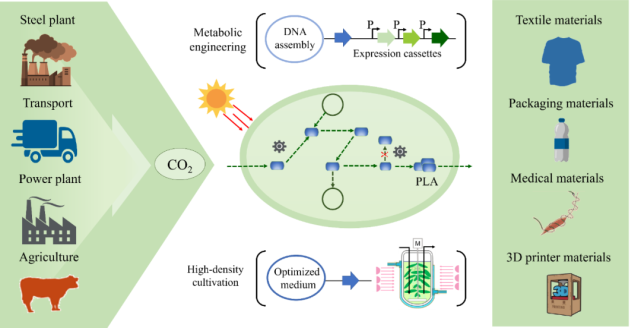

They used a combined strategy of metabolic engineering and high-density culture on a light-driven cyanobacteria platform to directly synthesize degradable plastic PLA using carbon dioxide as a raw material for the first time in the world.

This technology can not only solve the problems of plastic pollution and the replacement of non-grain raw materials in PLA production, but also directly capture carbon dioxide in the process of synthesizing PLA, helping "carbon neutralization" and "carbon peaking".

Source:Green Chemistry

This new generation of PLA production technology is completely different from the previous PLA manufacturing ideas. For the first time, the team established an autotrophic microbial cell factory to directly use carbon dioxide as a raw material to realize the biosynthesis of PLA in one step.

After 3 years of continuous exploration and technical iteration, the team has overcome difficulties such as carbon flow redirection, low cyanobacterial biomass, and slow growth rate in the research of PLA synthesis.

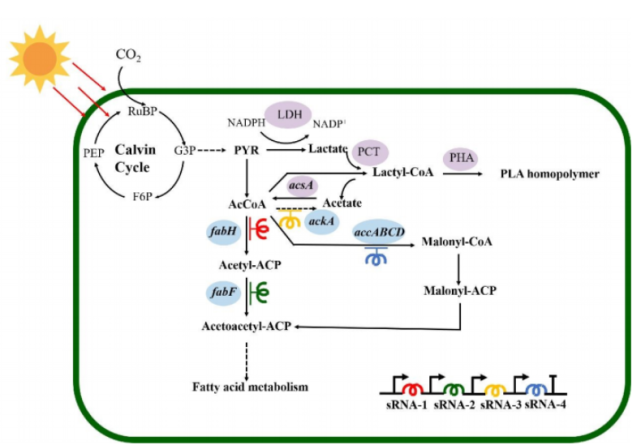

Synthetic pathway of carbon dioxide autotrophic synthesis of PLA(Source:Green Chemistry)

On the one hand, solving the problem of carbon flow redirection, in simple terms, is how to enable carbon to finally flow to the polymer PLA after carbon dioxide enters the cell.

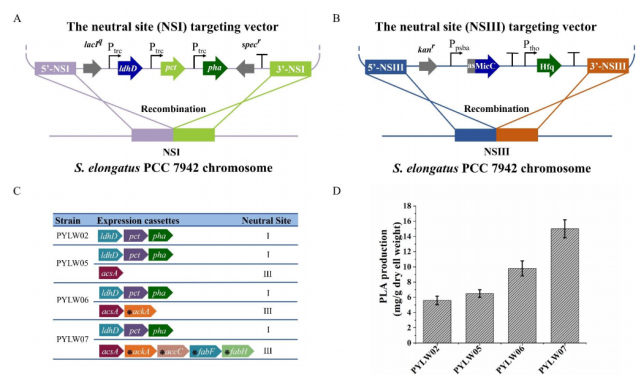

To solve this problem, the team tried a variety of approaches and did a lot of work in systems metabolic engineering. By optimizing the expression levels of key enzymes, the expression of propionyl-CoA transferase (propionyl-CoA transferase) and polyhydroxyalkanoate synthase (polyhydroxyalkanoate synthase) is enhanced.

At the same time, 4 genes of cyanobacteria were knocked down using a combination of sRNA tools, the carbon flux was redirected to PLA biosynthesis, and the cofactor self-circulating system was used to increase the supply of coenzymes, which significantly increased the production of PLA.

On the other hand, due to the characteristics of cyanobacteria, their growth density is not high enough and their growth speed is not fast enough.

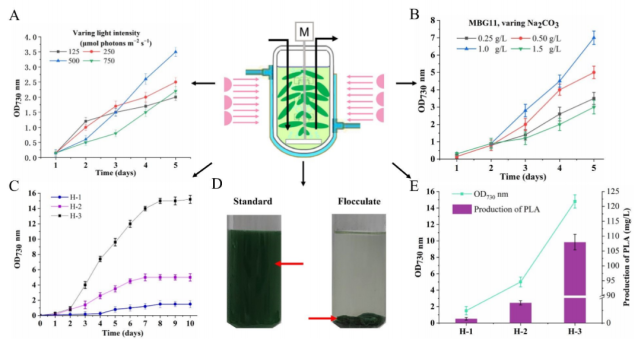

In response to this process problem, the team independently developed a new type of photoreactor, optimized the spectrum in a series, and adopted a controllable gradient light intensity method to make cyanobacterial cells grow faster and denser. At the same time, they also increased biomass using methods such as micro-stomata aeration, media optimization, etc.

Through a combined strategy of metabolic engineering and high-density culture, the researchers increased the cell density of cyanobacteria by a factor of 10. Under the optimal culture conditions, the highest cell density of cyanobacteria reached OD730nm 15.0 within 7 days, and the PLA concentration it produced was 108.0 mg/L, which was about 270 times higher than that of the initially constructed strain.

Tao Fei believes that this indicator is very close to the growth level of yeast. At the same time, this also shows that cyanobacteria still have great metabolic potential to be tapped.

Schematic diagram of PLA production strategy for high-density culture(Source:Green Chemistry)

In addition, the product recovery of this technology is more economical than the traditional production of small molecule compounds using cyanobacteria. A major challenge in the production of products by cyanobacteria is that the concentration of the synthetic product is low, and the extraction of the product requires operations such as concentration, which are complicated in steps, large in energy consumption, and high in product recovery costs.

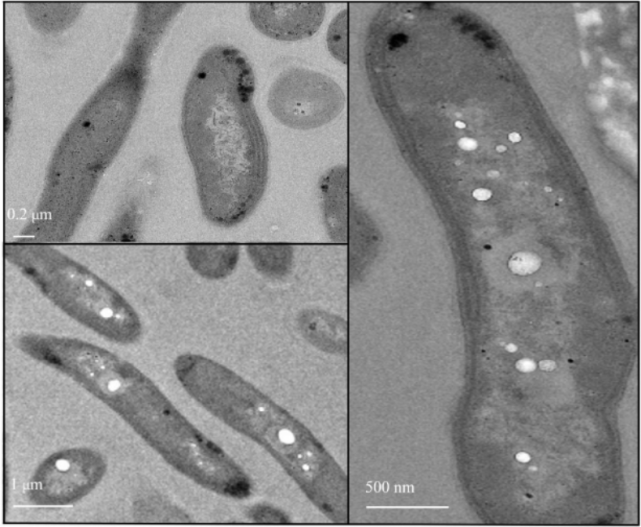

Instead, this technique accumulates solid products directly inside cyanobacterial cells. The self-developed "flocculation method" by the team does not require the use of energy-intensive "centrifugation methods" to allow the cells to settle naturally at the bottom of the container after they mature. The experimental results show that after 5 minutes of gravity settling, the flocculation rate is greater than 99%.

Tao Fei said that through the transformation of these metabolic engineering and the high-density culture process, the yield of PLA has been increased by more than 20 times. Moreover, the molecular weight of PLA in cyanobacterial cells (Mw, 62.5 kDa; Mn, 32.8 kDa) is one of the highest levels of biopolymerization reported in the literature so far, which can meet the needs of various applications of PLA.

When producing PLA, use different expression optimizations(Source:Green Chemistry)

Compared with other technologies, this technology has the effect of "three birds with one stone".

First, solve the problem of plastic pollution. The fundamental solution to white pollution is to use degradable plastics instead of traditional non-degradable plastics. The new generation of PLA production technology provides a sustainable development strategy for the production of degradable plastics, thus providing a guarantee for the replacement of degradable plastics.

Second, solve the potential problems of "competing with people for grain" and "competing with grain for land" in PLA production. It is worth noting that the synthesis of degradable plastics using sugar-based compounds as raw materials is not a sustainable development strategy for PLA that requires mass production. This process needs to consume a lot of grain, and the large-scale rollout of its manufacturing process will inevitably face the problem of "competing with people for grain" or "competing with grain for land".

This new technology "simplifies" the synthesis process, and transforms the long synthesis process of "carbon dioxide-grain-starch-sugar-lactic acid-lactide-PLA" into a synthetic "long chain" (metabolic pathway) into cells, directly using carbon dioxide as raw material, and no longer relying on food raw materials.

Third, carbon dioxide is directly captured in the synthesis process of PLA, and carbon dioxide is "turned waste into treasure", which can reduce carbon and help "carbon peak". Using waste greenhouse gases as raw materials to produce materials enables the manufacture of high-value products while reducing carbon emissions, which is more economically attractive and can help accelerate the development of carbon reduction.

It can be said that the technology has multiple benefits of economy, society and environment, as well as the prospect of industrial production.

From the national macro policy level, we have experienced the change from the "plastic restriction order" to the "plastic ban order".

In December 2007, the General Office of the State Council issued the "Notice on Restricting the Production and Sales of Plastic Shopping Bags"; in January 2020, the National Development and Reform Commission and the Ministry of Ecology and Environment issued the "Opinions on Further Strengthening the Control of Plastic Pollution".

In addition, the market size of plastics cannot be ignored. According to the data of Grand View Research, a U.S. investigation agency, "the size of China's plastic packaging market in 2019 was US$54.1 billion, and it is expected that by 2025, the size of China's plastic packaging market will reach US$69.8 billion. Based on a 30% replacement rate of degradable plastics, it is estimated that the market size of China's degradable plastic packaging in 2025 will be about 20.9 billion US dollars."

This technology of producing degradable plastics through cyanobacteria provides new ideas for the large-scale production of polymers. The key to the industrialized mass production of this technology depends on the cost of production. According to the team's estimates, this new PLA production method will be lower than the production cost of existing degradable plastics.

Tao Fei said the production costs here do not take into account changes in market conditions. For example, the price of sugar-based raw materials has risen, and carbon trading and carbon tax policies have been introduced. Once these market factors change, the cost advantage of the technology will be further enhanced.

Accumulation properties of PLA homopolymers in engineering(Source:Green Chemistry)

So, what are the possibilities for the future development of this technology?

On the one hand, the approach merges carbon reduction with plastic production. The team plans to use a carbon-free sustainable development method in the future - directly using electricity generated by solar energy or new energy as energy to produce PLA, using carbon emissions from power plants or directly using carbon dioxide in the air as a carbon source. This is in line with the "carbon emission reduction" and "carbon peak" model advocated by the world. In the future, a "negative carbon" manufacturing industry will be formed, and it will also bring economies of scale.

On the other hand, the technology brings dual environmental benefits. Both plastic pollution and climate warming are important environmental concerns. Degradable plastics are still in the early stage of development, and replacing traditional plastics with degradable plastics is the future development trend, which also means that there are huge development prospects in this field. Solving the greenhouse effect by reducing carbon has also become an international development trend. The technology provides a solution to both environmental problems at the same time.

In addition, the technology can be used for high-performance PLA fabrication. Currently, PLA is widely used in chemical, medical, pharmaceutical and 3D printing fields. Compared with the traditional chemical method, the technology adopts biological synthesis, and there is no problem of heavy metal catalyst residues, which makes the PLA produced by this technology have a broader application prospect in high-end fields.

For example, Tao Fei said: "For example, for medical surgical sutures, the PLA in it is not allowed to contain heavy metals, and the biosynthetic PLA can meet this requirement."

Source:Green Chemistry

According to reports, the team's next research focus is to increase the proportion of PLA's dry cell weight, and it is planned to further increase the proportion of dry cell weight to more than 50%.

Tao Fei said that, on the one hand, the key enzymes were modified by means of protein engineering. "We found some problems with the catalytic performance of the enzyme, and its structure has been predicted with AlphaFold2, and in-depth protein engineering research is underway. Next, we will focus on how to improve its affinity for precursor substances and PLA. The speed of chain polymerization can improve the catalytic efficiency of the enzyme, so that the overall production capacity of PLA is higher," he said.

On the other hand, prepare for industrial production. The team hopes to further improve the robustness of the cell chassis, including a series of tolerances, such as high light resistance, pollution resistance, and salt resistance. In addition, the team also plans to conduct related research on the self-flocculation of cells before the pilot test of the product.

The team also has a clear plan for the future development of the technology. Tao Fei said, "We plan to carry out pilot testing and optimization of the entire chain through continuous investment of 3-5 years, and improve all indicators to the level of industrialization."